Descripción del producto

Medición continua y precisa del nivel de llenado en depósitos y recipientes abiertos sin presión, así como en aplicaciones subterráneas como fosas, pozos y perforaciones

Datos técnicos

Propiedades

- Clase de protección EN60529

- IP 65

- Temperatura de funcionamiento

- -10...70 °C

- Temperatura de almacenamiento

- -25...70 °C

- Fuente de alimentación

- 15...30 V DC

- potencia

- max. 25 mA

- Salida

- 2-Leiter-Technik | 4...20 mA

- Rango de medición

- 0,8...10 mWs (Standard)

- Sobrepresión

- ca. 20 %

- Desviación de la curva característica

- Nichtlinearität,

- Resistencia del aislamiento

- > 100 kΩ

- Resistencia al cortocircuito

- permanent

- Protección contra inversión de polaridad

- keine Schädigung o. Funktion bei vertauschten Anschlüssen

Materiales

- Carcasa

- Edelstahl 1.4571, PVC, PVDF

- Celda de medición

- Edelstahl 1.4404, Keramik AI2o3 96%, Keramik AI2o3 99,9%

- Juntas

- FKM (Viton ®), EPDM, FFKM (Kalrez ®)

- Rosca de conexión

- G ¾“ | G 1 ½“

- Enchufe

- Steckverbindung DIN 43650

HD-110 | HD-112 | HD-114 Configurar

HD11 - [ 1 ] - [ 2 ] - [ 3 ] - [ 4 ] - [ 5 ] - [ 6 ] - [ 7 ]

product description

Más información del producto

Las sondas hidrostáticas (sondas de nivel) se basan en la medición de presión en un líquido en reposo sometido a un campo gravitatorio homogéneo. Esta presión se denomina presión hidrostática. La presión hidrostática en un líquido aumenta de forma proporcional a la altura de llenado. Es decir, cuanto mayor es la columna de líquido, mayor es también la presión, por ejemplo, en el fondo de un tanque.

Gracias a este principio de medición, las sondas hidrostáticas permiten una medición continua y precisa del nivel en depósitos y recipientes abiertos sin presión, así como en aplicaciones subterráneas como pozos, arquetas o perforaciones. Las sondas Fluid.iO HD del tipo HD-1XX son adecuadas, según su diseño, para su uso en agua, líquidos limpios o ligeramente contaminados, ácidos, álcalis y medios agresivos.

Según el tipo de acceso disponible, el nivel se detecta mediante sondas de inmersión o de rosca. La presión hidrostática del medio actúa sobre la célula de medición de presión de la sonda y se convierte directamente en una señal electrónica estándar, que permite mostrar el nivel de forma analógica, por ejemplo, en m, % o l.

Ventajas de las sondas hidrostáticas de Fluid.iO

| Preciso y fiable | Versátil | Sencillo diseño del dispositivo |

|

|

|

Funcionamiento y principio de medición

Las sondas Fluid.iO HD miden la presión hidrostática. Con un mismo nivel de llenado, la presión hidrostática en todos los recipientes es igual, independientemente de su forma (paradoja hidrostática).

En depósitos abiertos, la presión en el líquido resulta de la suma de la presión generada por el peso de la columna de líquido y la presión del aire (presión atmosférica) por encima del nivel del líquido. En las sondas hidrostáticas, en el extremo inferior se encuentra una célula de medición de presión, que capta la diferencia entre ambas presiones. De este modo, posibles variaciones de la presión atmosférica causadas por cambios meteorológicos o diferentes ubicaciones de medición quedan compensadas. La presión ejercida sobre la célula de medición se convierte, mediante una electrónica de evaluación integrada, en una señal de salida correspondiente.

P = ρ * g * h | P = presión| ρ = densidad del líquido| g = gravedad| h = altura

La señal de salida de la sonda HD puede convertirse en una altura de nivel. Es importante tener en cuenta que la presión hidrostática depende de la densidad del líquido. Un líquido con mayor densidad, como el agua, ejerce más presión en el fondo que un líquido con el mismo volumen pero menor densidad, por ejemplo el aceite.

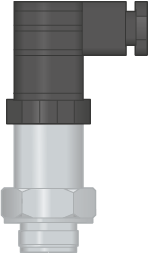

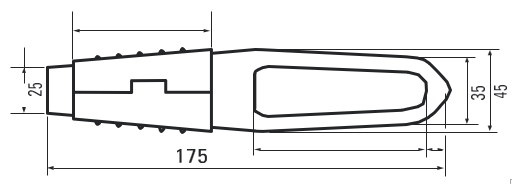

Variantes de ejecución

Las sondas hidrostáticas están disponibles como sonda de inmersión para montaje suspendido desde la parte superior, y como sonda de rosca para montaje en la pared del depósito. Para garantizar la mayor resistencia posible, se pueden fabricarse con distintos materiales para el cuerpo, la membrana de medición, las juntas y el cable. Las configuraciones específicas del producto se pueden consultar en la clave de tipo del folleto técnico correspondiente.

Línea de productos |

||||||

| Sondas hidrostáticas |

HD-100

|

HD-102

|

HD-104

|

HD-110

|

HD-112

|

HD-114

|

| Producto o número de catálogo | D-02-01-01 | D-02-01-02 | ||||

Diseño |

||||||

|

Tipo de producto 0 = Sonda de inmersión |

0 | 0 | 0 | 1 | 1 | 1 |

|

Material de la carcasa 0 = Acero inoxidable |

0 | 2 | 4 | 0 | 2 | 4 |

Material de la célula de medición |

||||||

| Acero inoxidable 1.4404 | ✔ | ✔ | ||||

| Cerámica AI₂0₃ 96 % | ✔ | ✔ | ✔ | ✔ | ||

| Cerámica AI₂0₃ 99,9% | ✔ | ✔ | ✔ | ✔ | ||

Material de la junta |

||||||

| Viton | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| EPDM | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Kalrez | ✔ | ✔ | ✔ | ✔ | ||

Conexión eléctrica |

||||||

| Cable PVC | ✔ | ✔ | ✔ | |||

| Cable PUR | ✔ | ✔ | ✔ | |||

| Cable FEP | ✔ | ✔ | ✔ | |||

| Conector en forma A | ✔ | ✔ | ✔ | |||

Rosca de conexión |

||||||

| G 3/4" | ✔ | |||||

| G 1 1/2" | ✔ | ✔ | ||||

Ampliación del sistema

Para la visualización del nivel, así como para la monitorización de valores límite y el control sencillo de bombas u otros dispositivos, las sondas HD pueden complementarse con dispositivos de visualización y evaluación adicionales:

- Indicadores de barra luminosa tipo TK-320 y TK-321

- TK-313 und TK-315 …

- Indicadores digitales de fácil programación tipo AD-310 y AD-313

Estructura del sistema

El sistema de medición de la serie HD-1xx está compuesto por una sonda hidrostática (de inmersión o de rosca) y un dispositivo de evaluación o un indicador digital.

El indicador digital programable AD-313, diseñado para montaje en panel, permite mostrar unidades personalizadas (litros, etc.) como valores de nivel gracias a su función de escalado. Además, permite configurar valores límite que pueden ser monitorizados mediante salidas de relé con función de alarma.

Los dispositivos de evaluación TK-313 y TK-315 son versiones compactas para montaje en carril DIN. En ambos casos se muestra el nivel en porcentaje. El modelo TK-313 permite la monitorización de 2 valores límite, y el TK-315 permite 4 valores límite mediante salidas de relé.

Conexión eléctrica

La sonda hidrostática proporciona el valor medido del nivel como señal de corriente de 4…20 mA en configuración de 2 hilos.

Accesorios de montaje

Como accesorios de montaje están disponibles una caja de conexión con elemento de compensación de presión, así como racores de acero inoxidable, PVC, PVDF, abrazaderas de sujeción y, si se desea, montaje sobre una brida.

Documentos y descargas

Hoja de datos

Instrucciones de instalación y funcionamiento

Declaración de conformidad

Productos relacionados

TK-315

Equipo de evaluación con 4 contactos de límite (contactos normalmente abiertos).

Ir al producto